Sarah Hoit05.19.15

Concern for the health of our planet and future generations is as strong as ever, but brands and customers are expecting ecologically focused attributes in a new way. No longer is “sustainable” a visual descriptor; it should fit within a brand’s aesthetic. Thinking back 10 years, ecological packaging used to be very niche, highly visible, clearly differentiated and “crunchy.” No longer is this the default.

The author, Sarah Hoit

Common commodity materials currently fulfill today’s trends of transparency, tonal metallics and new blacks. Developments in sustainable packaging can serve these CMF trends as well: Can a high-quality look and feel make for seamless integration of ecological choices and help move toward an expected norm?

Clear Focus

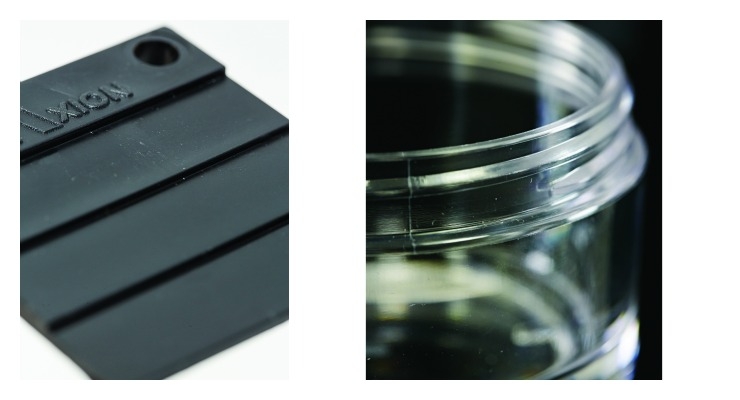

There are many transparent offerings on the market today, and the high clarity and chemical durability of these plastics can be hard for biopolymers to match. For transparent biopolymers, PLA (polylactic acid) most often comes to mind, but there are other bio-based polymers that offer high clarity and more of the physical properties needed for use in the packaging industry. EcoZen from SK Chemical is a partially bio-based PEIT (polyethylene isosorbide terephthalate) that offers moldability for thick walled applications; it is highly heat stable and chemically resistant for primary packaging applications. Some bio-based materials are only created from rapidly renewable resources, but others use those agricultural resources to create the same petroleum based polymer chemistries widely in use today.

Shiny Solutions

Metallic effects in a range of tonal colors are in wide use currently. From mascara tubes and compacts to eyelash curlers and temporary tattoos, a touch of shine is everywhere. These effects are currently achieved through a range of processes: PVD, vacuum metallization or hot foil stamping. Other techniques are being developed to bring metallic effects into new arenas and without the use of actual metal. Fi-cell from Toyo creates metallic effects in blow-molded bottles through the creation of micro bubbles during molding, which scatter light and create a metallic finish. The preform is injected with liquid nitrogen, which converts into bubbles when heated, which are then elongated during blowing. The process can be used with any color and also serves to decrease the packaging weight. The single material composition of the bottle aids in recycling compatibility, benefiting end of life as well.

The New Black

Any season may have the “new black” but it never stays, unlike the moniker’s originator and perennial favorite, black. The enduring popularity of black primary packaging offers an interesting sustainable sourcing opportunity. Recycled polymers are improving in availability, polymer variety, quality, and cleanliness. Axion Polymers offers fully traceable to point of origin post consumer recycled resins in PP (polypropylene), PS (polystyrene) and ABS (acrylonitrile butadiene styrene). One of the challenges to adoption of recycled polymers is lack of color options. Due to mixed sourcing, many recycled resins are available in two colors: off black and black. Due to the prevalence of blacks in primary packaging, these plastics needn’t be relegated to internal automotive components; they can be considered ready to go in the longest-standing color trend. Additionally, as the composition is the same as currently used virgin resin, established processing and finishing techniques are compatible.

These and many other developments in materials continue to meet shifting trends of all types. Thoughtful material choices are able to serve the aesthetic and performance needs of a package, and lessen our impact on the planet without sacrificing their primary function as brand ambassador.

About the Author

The author, Sarah Hoit

Clear Focus

Shiny Solutions

Metallic effects in a range of tonal colors are in wide use currently. From mascara tubes and compacts to eyelash curlers and temporary tattoos, a touch of shine is everywhere. These effects are currently achieved through a range of processes: PVD, vacuum metallization or hot foil stamping. Other techniques are being developed to bring metallic effects into new arenas and without the use of actual metal. Fi-cell from Toyo creates metallic effects in blow-molded bottles through the creation of micro bubbles during molding, which scatter light and create a metallic finish. The preform is injected with liquid nitrogen, which converts into bubbles when heated, which are then elongated during blowing. The process can be used with any color and also serves to decrease the packaging weight. The single material composition of the bottle aids in recycling compatibility, benefiting end of life as well.

The New Black

Any season may have the “new black” but it never stays, unlike the moniker’s originator and perennial favorite, black. The enduring popularity of black primary packaging offers an interesting sustainable sourcing opportunity. Recycled polymers are improving in availability, polymer variety, quality, and cleanliness. Axion Polymers offers fully traceable to point of origin post consumer recycled resins in PP (polypropylene), PS (polystyrene) and ABS (acrylonitrile butadiene styrene). One of the challenges to adoption of recycled polymers is lack of color options. Due to mixed sourcing, many recycled resins are available in two colors: off black and black. Due to the prevalence of blacks in primary packaging, these plastics needn’t be relegated to internal automotive components; they can be considered ready to go in the longest-standing color trend. Additionally, as the composition is the same as currently used virgin resin, established processing and finishing techniques are compatible.

These and many other developments in materials continue to meet shifting trends of all types. Thoughtful material choices are able to serve the aesthetic and performance needs of a package, and lessen our impact on the planet without sacrificing their primary function as brand ambassador.